Mar

28

Mar

28

Machining

- March 28, 2021

- 0 Comment(s)

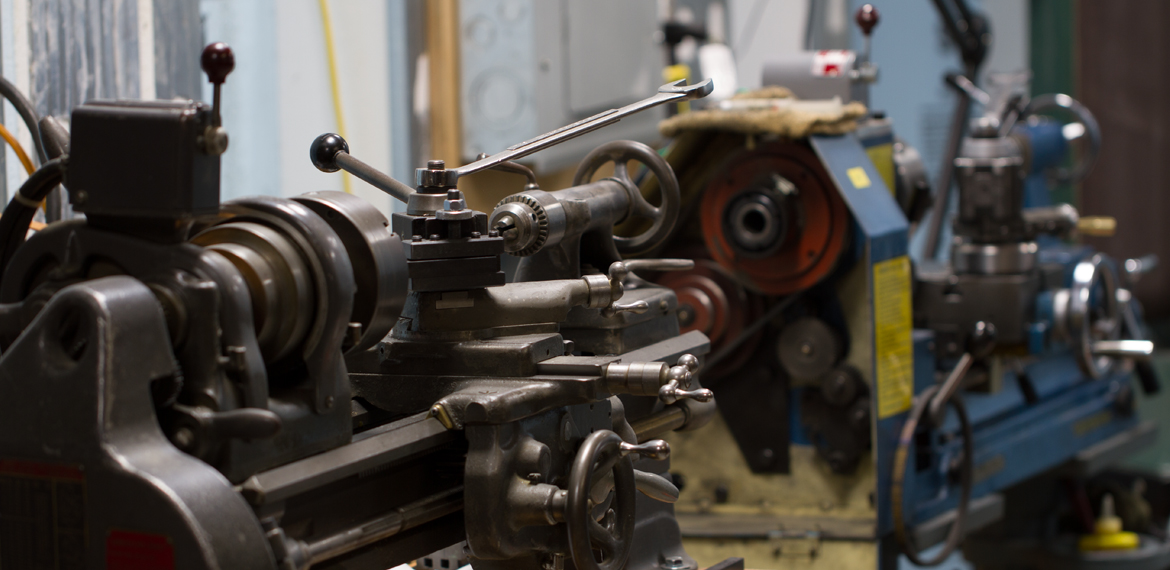

3D Printed Solid’s machining capabilities include manual equipment such as lathes, a mill, a drill press, saws, a rotary table, grinders, sanders, and an array of various measuring equipment; everything needed to enhance our production and prototyping capabilities.

All of our 3D printers (that we use on a daily basis) have been modified to improve the overall performance of the printers. Through many years of testing different printer heads, nozzles, and auxiliary parts we have fine tuned our printers to make the highest quality prints possible in a reasonable amount of time. There are many factors which go into the design of a 3D printer; 27 years experience in extrusion design and working daily with plastics sets us apart from the rest of the crowd.

Another use for our machining equipment comes from concept-proofing or prototyping. When we need a high strength part or a high-wear resistance application, we use other materials such as stainless steel, steel, aircraft grade aluminum, brass, as well as formulated resins/polymers. Different applications require different materials and methods to achieve a high quality part. Moving parts such as Nerf Rival flywheels can turn up to 30,000+ RPM. They take a lot of repetitive stress from ball impact. The cyclic motion of impacting balls at a given rate can introduce vibrations at high RPMs. Therefore having a true and balanced flywheel is critical to performance and safety, only achieved through tight tolerances. This is the reason we use high quality resins for our flywheels; we turn them on a lathe to hold greatly improved dimensions and concentricity over other methods.